At present, a "hood" is hard to find. In this situation, various types of masks such as medical protective masks, medical surgical masks, disposable medical masks, N95 protective masks have become tight supplies. What are the differences between different types of masks? What are the standards of masks? How should I choose? Knitted masks are not counted as masks? Are antibacterial masks really antibacterial? Recently, we specially invited Professor Gong Yi from the School of Materials Design and Engineering of Beijing Institute of Clothing Technology to give Everyone makes a detailed interpretation.

Professor Gong Yue is currently working at the Institute of Textile and Apparel of Tarim University in Xinjiang. His team is involved in the research and development of a variety of masks, has many national patents, and has won the National Invention Gold Award. Mr. Gong's Beijing Institute of Clothing is currently working on the research and development of high-performance composite fiber cloth and antibacterial mask technology and testing evaluation. The main contents of this project include: optimization of the meltblown process of high-loaded charge fiber membranes, and composite fibers. Relationship between characteristics and air resistance and filtration efficiency, performance evaluation of new renewable composite fiber cloth, application of antibacterial composite functional materials in masks, etc.

1.Mask material, structure and working principle

Mask material:

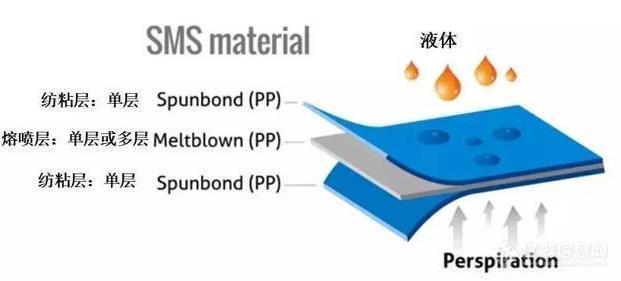

Medical masks are generally made of three layers of non-woven fabrics: spunbond non-woven fabric, meltblown non-woven fabric, and spunbond non-woven fabric. The outer layer of the mask has a water blocking effect, the middle layer filters, and the inner layer absorbs moisture. Non-woven fabric is a kind of fabric that does not require spinning and weaving. It is not interwoven and knitted by individual yarns, but rather the fibers are directly bonded together by physical methods. Spunbond nonwovens and meltblown nonwovens are both types of "nonwovens". Meltblown non-woven fabrics are characterized by small fiber diameter and large specific surface area, which can filter particles in the air well, but have low strength and poor abrasion resistance. The spunbond fabric has a relatively high linear density, and the web is composed of continuous filaments. Its high strength can just make up for the shortcomings of meltblown fabrics.

Working principle: Take medical surgical masks (ordinary 3-layer flat non-woven masks) as an example. The structure includes an outer non-woven fabric to prevent splashing liquid and large particles; a middle-layer electrostatic meltblown non-woven fabric (polypropylene), that is The electric layer uses electrostatic adsorption to effectively block tiny particles, especially particles or droplets carrying nano-scale viruses, to effectively block particles such as viruses; the inner layer of non-woven fabric is used to block exhaled water vapor. The principle of mask filtering mainly uses electrostatic adsorption and the blocking of fine particles and droplets after the fibers are arranged. The charged layer in the middle of the mask plays an important role in protecting particles or droplets carrying viruses and bacteria. During the use of the mask, due to the deposition of bacterial viruses and particulates in the electrostatic layer and the loss of static electricity from the charged layer due to the gas (water vapor), the electrostatic adsorption effect is lost, which significantly damages its filtering effect, especially the effective blocking of particles such as viruses. In an emergency, if you want to reuse the mask, you need to focus on two points: first, how to kill and remove the bacteria and viruses deposited on the mask; and second, how to add static electricity to the intermediate charge layer. Therefore, the key technical problem of reusable masks is how to recharge the middle layer non-woven fabric to regenerate the electrostatic adsorption effect without damaging the mask material and microstructure.

Mask design example:

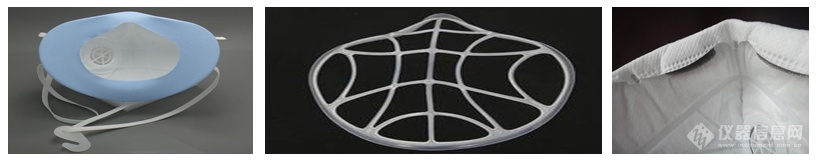

Air-tight design: The mask uses a large area of blue air-tight fin edges. This layer of seemingly thin blue material is the most technologically advanced part of the entire mask. It has a certain amount of rubber through the combination of elastic rubber and fabric layers. Elasticity, extremely high air tightness and hydrophobicity. When worn, this layer of blue fin edges can fill the gap between the two, regardless of whether the mask is suitable for the user's face shape. The folded-back edge is close to the face curve, distributing the same pressure to a larger contact area, making the pressure smaller, achieving a more comfortable wearing experience, and greatly reducing the risk of leakage caused by the gap caused by the contact of the curved surface of the face. Therefore, this style of mask only requires one size in principle.

Mask frame design: The PP material frame has a certain elasticity. After supporting the mask, it provides a large space inside the mask, which greatly increases the breathing buffer space. At the same time, the mask filter material will not swell or swell with the breath. There is no chance that the mouth or nose bridge touches the inside of the mask.

Use of multi-layer filter media : Multi-layer filter media design, four-layer composite structure. The two outermost layers are non-woven fabric layers that have no filtering ability and mainly protect the inner layer of filter material. The middle two layers are white meltblown fiber layers. Meltblown fibers are very dense. Usually manufacturers charge electrostatic charges in them and filter and retain fine particles through physical blocking and electrostatic adsorption. Compared with the common single-layer meltblown fiber layer, if two thick and thin meltblown fibers are used, the filtration rate should be higher than that of the single layer.

Nose clip design: Polyurethane nose clips that are more suitable for Asian nose bridges can be used. The white polyurethane nose clip is smaller than the common large-area metal nose clip and is also a non-toxic and environmentally friendly material, so it can better fit the nose bridge that is generally not high in Asians and reduce the environmental burden. In the inner position corresponding to the nose clips, two distinctive sponge bulging nose pads are deliberately set, which just fill the positions where the sides of the nose wings are most likely to leak when wearing a mask.

Head rope design: The common metal nail fixed head rope has the risk of allergies. The ultrasonic welding head rope adopts a vertical connection design. Users can easily find a comfortable wearing angle and pulling force by adjusting it up and down. At the same time, this design also caters to the wearing needs of users wearing glasses, and avoids the embarrassment of the general elastic rubber band mask being pulled off or bounced to the face when worn.

What is the difference between different masks?

What are the differences between medical protective masks and ordinary N95 protective masks?

Medical protective masks are government-approved protective masks designed to protect medical workers in a specific medical environment. Both medical protective masks and ordinary N95 protective masks have respiratory protection for particles suspended in the air. However, There are additional requirements for protective masks for use in medical environments. On the one hand, in order to prevent infection of the patient during the operation or treatment of the medical staff to the patient, the medical mask worn must be able to block the wearer's breathing and speaking droplets and bacteria from entering the operating environment, and the mask itself must be hygienic. Therefore, the original number of microorganisms on the mask cannot exceed the limit, and no breather valve is allowed on the mask; on the other hand, in order to prevent high-pressure infectious body fluids generated during surgery or treatment from splashing on the mask and penetrating into the wearer, Mouth and nose cause medical staff to be infected. Medical masks must be able to resist the penetration of pressured blood and body fluids. These two requirements are actually the main requirements for medical surgical masks. Medical protective masks must have the functions of ordinary N95 protective masks and medical surgical masks, while ordinary N95 protective masks do not need to have the ability to prevent blood and body fluid penetration of medical surgical masks and medical protective masks, and control requirements for microorganisms. Therefore, it is a misconception that only medical protective masks can prevent bacteria and viruses. In addition to being used by medical workers to protect against high-pressure body fluid splashing, ordinary N95 protective masks or masks with equivalent performance can be used for protection.

KN95 mask, N95 mask

Is a protective mask with exhalation valve optional?

The role of the exhalation valve is to reduce the exhalation resistance of the protective mask. Medical protective masks are not allowed to have an exhalation valve because an open exhalation valve may discharge droplets or bacteria generated by the wearer of the mask, which may threaten patients undergoing surgery. Therefore, if you are wearing a protective mask to help you prevent the virus, it is not a problem to choose a more comfortable protective mask with an exhalation valve; but if a person suspects that they are infected or has been infected by some virus, they should take the initiative to wear without breathing The benefits of valve masks are that they both protect themselves and avoid infecting others.

Are knitted masks protective?

Knitted masks, as the name suggests, are knitted masks made of knitted fabrics. At present, there are many knitted masks on the market. The testing standard is FZ / T 73049-2014. The main testing types and basis are:

GB / T 2910 (all parts) Quantitative chemical analysis of textiles

GB / T 2912.1 Determination of formaldehyde in textiles. Part 1: Free and hydrolyzed formaldehyde (water extraction method)

GB / T 3920 Textile color fastness test

GB / T 3921—2008 Textile color fastness test

GB 9994 textile material moisture regain

GB / T 17592 Determination of banned azo dyes in textiles

GB 18401 National Safety Technical Specification for Textile Products

FZ / T 01057 (all parts) Textile fiber identification test method

FZ / T 01095 Test method for fiber content of textile spandex products

GSB 16-2500 knitted fabric surface defect color sample 3 specifications

Its main testing content includes intrinsic quality and appearance quality. Intrinsic quality includes pH value, formaldehyde content, odor, decomposable carcinogenic aromatic amine dye, fiber content, fastness to soaping, fastness to water, fastness to saliva, fastness to rubbing, fastness to perspiration , Air permeability and other indicators; appearance quality includes surface defects, sewing regulations and other indicators. The inherent quality requirements are shown in the table below.

As a knitted mask, if you want to have a better protection effect, it is recommended to choose to have the national mask protection standard GB2626-2006 testing index in addition to the general textile standard "FZ / T 73049-2014". In this way, the masks that pass the test and evaluation can have a protective effect.

Are antibacterial masks really antibacterial?

The operating environment of medical surgical masks requires that the masks have the function of blocking the penetration of bacteria. The industry standard requires that the bacteria filtering efficiency of the masks should be above 95%. Bacterial filtration efficiency test method: The bacteria filtration efficiency test uses Staphylococcus aureus to make a bacterial suspension, and an aerosol generator is used to generate a bacterial aerosol. After the aerosol is filtered through a mask, the six-stage Anderson sampler is used to collect the filtered bacteria. After culturing and colony counting, the number of bacteria that passed through the mask and not blocked was obtained as the data of the test group, and compared with the positive control group that collected the aerosol bacteria directly from the sampler without filtering through the mask to obtain the mask. Bacterial filtration efficiency. In the actual testing process, the bacteria liquid concentration, aerosol flow rate, and sampling time have specific requirements, and the number of colonies needs to be corrected to ensure the authenticity of the experimental results.

In the new version of YY 0469-2011 standard, a new bacterial filtration efficiency experiment system is adopted. Based on the 2004 version of the traditional experiment system, an innovative improvement is adopted. The dual gas path simultaneous sampling method is adopted, that is, the test group and the positive control group are simultaneously. Collecting the number of bacteria in the same aerosol, this synchronous sampling method improves the sampling accuracy and test efficiency, and the new test system adopts a negative pressure design as a whole, which can ensure the safety of the operator.

In the new version of YY 0469-2011 "Technical Requirements for Medical Surgical Masks," the technical requirements for filtration efficiency are non-oily particle filtration efficiency ≥30% and bacterial filtration efficiency ≥95%. Among them, non-oily particle filtration efficiency requirements are low and bacterial filtration efficiency requirements The value is higher. The results of this test show that when a mask meets both of these requirements, the filtration efficiency value of non-oily particles is often much higher than 30%, and the test results are significantly positively correlated. According to the test results, when the product has a high non-oily particle filtration efficiency, the feasibility of acting the particle filtration efficiency result instead of the bacterial filtration efficiency can be considered, that is, when the particle filtration efficiency value (PFE) of the medical surgical mask is higher than The specified value, such as 85%, can no longer perform bacterial filtration efficiency test, which can reduce the risk of hazards caused by pathogenic microorganisms in the laboratory, save testing resources and improve testing efficiency.

Third, the mask reuse operation

Hot water detoxification: Soaking used disposable medical non-woven masks in hot water for more than 56 ℃ for 30 minutes (refer to "New Coronavirus Pneumonia Prevention and Control Plan (Fourth Edition)", 56 ℃ for 30 minutes can effectively kill Live virus), inactivate the new crown virus, and wash away the dust. After washing, hang or dry the mask. [Usually 1: 1 volume ratio of boiling water and room temperature water (calculated at 20 ℃) is about 60 ℃ after mixing. In order to improve the effect of disinfection and sterilization, the proportion of boiling water can be appropriately increased. Note: Do not rub the mask during hot water immersion and disinfection to avoid damage to its microstructure; it is best to soak hot water in a pot for one person to avoid cross-contamination. 】

Charge regeneration: Place the mask after hanging / drying on the surface of dry, insulating material, and blow with a hair dryer for 10-20 minutes. The distance between the air outlet and the mask is about 10 cm (note the temperature at the outlet of the blower, not too high. Prevent scalding of mask fibers, which can be modeled after the hair is dried after shampooing). Alternatively, blow the mask with an ordinary electric fan for about 20 minutes and a distance of about 5 cm. Or use a static electricity generator such as an ordinary household electronic igniter to fully cover the "shock" of the mask to recharge the mask.

Paper scrap inspection: Sprinkle some dry paper scraps on the insulated table top, and close the outer layer of the recharged mask close to the paper scraps. The distance is greater than 1 mm but not directly in contact with the mask. The electrostatic adsorption phenomenon indicates that the mask has sufficient charge capacity and can be reused. [If the electrostatic adsorption phenomenon is not obvious, then extend the processing time of the second-stage charge regeneration, and pass the "paper scrap adsorption" again to check the charge condition of the regeneration mask, until the charge is sufficient and can be reused. 】

Reprinted from: [Instrument Information Network]

related suggestion

- ·【industry news】

A quick overview of the full t

- ·【industry news】

The National Health and Health

- ·【industry news】

The new version of "Drinking W

- ·【industry news】

5 water quality testing standa

- ·【industry news】

Catalogue of National Food Saf

share to:

keywords: the new laboratory analytical instruments, intelligent pre-processing equipment